RC Car Tires A Guide to Ultimate Racing Grip

When it comes to on-road RC racing, let's get one thing straight: your RC car tires are the single most important part of your car. Period. They are the only piece of your high-performance machine that actually touches the track. Everything else—the motor, the chassis, the setup—is useless if that connection isn't right.

Think of them less like simple rubber rings and more like a set of specialized athletic shoes, each one designed for a specific surface and condition. Get it right, and you're flying. Get it wrong, and you're fighting the car every corner.

Your Foundation for Victory: Understanding RC Car Tires

Every seasoned racer knows this truth. You can have the most powerful motor on the grid, but without the right tires, all that power just turns into wheelspin. This is where digging into the anatomy of a tire really pays off. Each part works together to turn your steering and throttle inputs into clean, fast laps. Understanding how they interact is the first step to making smarter choices that actually win races.

The Core Components of an RC Tire

Just like on a full-size race car, an RC tire is a system. Every piece has a job, and how they all work together defines how the tire behaves on track.

- Carcass: This is the tire's skeleton. Its shape and the stiffness of the sidewalls decide how the tire flexes under the brutal forces of cornering. A stiffer carcass gives you a razor-sharp, immediate response, while a softer one can be more forgiving and generate more grip on bumpy surfaces.

- Bead: This is the inner edge of the tire that locks onto the wheel. A rock-solid bond here, usually made with CA glue, is absolutely critical. If that bond fails, the tire will peel right off the rim mid-corner—and your race is over.

- Insert: This is the foam ring tucked inside the tire. It’s basically the tire’s air pressure system, providing support to the carcass and dictating how the tread sits on the track. The density of the foam is a massive tuning tool for racers.

This obsession with tuning is a global phenomenon. The RC car tire market was valued at roughly USD 551 million in 2024, and North America makes up a huge slice of that pie at around USD 200 million. Those numbers are only going up, which just shows how serious this hobby has become.

The Wheel and Its Role

The wheel is far more than just something to glue the tire to; it's a key part of your suspension and handling package. The material, spoke design, and even the flexibility of the wheel change how the entire tire assembly performs. A more flexible wheel can actually generate more mechanical grip on some tracks, while a super-rigid one delivers a more direct, aggressive feel.

This whole ecosystem of parts is what separates the front of the pack from the midfield. To get a bigger picture of the hobby and how it all fits together, check out our guide on RC cars in Canada.

Decoding Rubber Compounds for Peak Track Grip

The secret to going fast in on-road racing isn't just about a powerful motor. It's about how effectively you put that power to the track. That's where the science, or maybe the art, of rubber compounds comes in. Think of your RC car tires like the soles on a pair of running shoes—soft, sticky soles are great for a clean gym floor, but you'd want something tougher for running on pavement. It's the exact same logic at the racetrack.

Every tire manufacturer has its own secret sauce—a specific blend of synthetic rubbers and additives engineered to work best within a pretty narrow window of conditions. The whole point is to find a compound that creates the most friction (what we call grip) on a certain surface at a specific temperature. Nailing this choice is often what separates the podium finishers from everyone else fighting to keep their car pointed in the right direction.

Understanding the Durometer Scale

So, how do we talk about tire hardness in a way that means the same thing to everyone? We use a tool called a durometer, which measures Shore hardness. This gives us a number, like "32 Shore" or "40 Shore," which is a standardized way to compare how soft or hard a tire is.

It’s a pretty simple scale to get your head around:

- Lower Shore Number: This means you’ve got a softer rubber compound. Softer tires deliver more grip, especially on cooler or lower-traction tracks, because the rubber can physically mould itself into the tiny imperfections of the surface. The trade-off? They wear out a whole lot faster.

- Higher Shore Number: This points to a harder rubber compound. Harder tires are way more durable and really shine on high-grip surfaces like carpet, or on really hot days. They keep the car from feeling "bogged down" or lazy in the corners and can take the heat without falling apart.

A classic rookie mistake is thinking the softest tire is always the fastest. Put an ultra-soft tire on a high-bite carpet track, and it can actually overheat, get greasy, and cause your car to traction-roll every time you try to turn. You'll end up being much slower.

Matching Compound to Track Temperature

If there’s one thing that dictates your tire choice for the day, it’s track temperature. Rubber is incredibly sensitive to heat, and its grip characteristics can change drastically as the track warms up or cools down. A tire that feels absolutely dialed in during the cool morning practice can turn into a slippery mess once the sun starts baking the asphalt.

This is exactly why you see experienced racers show up with a whole box of tires covering a wide range of compounds. They know that as the day goes on, they'll have to adapt their tire choice to stay on top of the changing conditions.

Let's walk through a quick scenario. You're at an asphalt track in the morning, and it's cool and a little dusty. A soft compound, maybe a 28 or 32 Shore, is going to be your best bet. The soft rubber will "bite" into the track, giving you the mechanical grip you need to get around a slick surface.

Fast forward a few hours. The sun is out, and the track temp has shot up by 10-15°C. That soft tire is now overheating. It feels gummy, and you might even see it start to grain up. That’s your signal to switch to a harder compound, like a 36 or 40 Shore. This harder tire will now be in its happy place, giving you consistent grip on the hot surface without wearing out in just a few minutes.

To make this a bit easier, here’s a quick reference guide to help you get started.

RC Tire Compound Selection Guide by Track Condition

| Compound Hardness (Shore) | Ideal Track Temperature | Best For Track Surface | Performance Characteristics |

|---|---|---|---|

| 24 - 28 Shore (Ultra Soft) | 10°C - 20°C (Cool) | Low-grip asphalt, dusty surfaces | Maximum mechanical grip, fast warm-up, but wears very quickly. |

| 30 - 34 Shore (Soft) | 20°C - 30°C (Mild) | Asphalt, low-bite carpet | Good balance of grip and wear for average conditions. |

| 36 - 40 Shore (Medium) | 30°C - 40°C (Warm/Hot) | High-bite asphalt, prepared surfaces, carpet | Consistent grip on hot or abrasive surfaces, good durability. |

| 42+ Shore (Hard) | 40°C+ (Very Hot) | High-grip carpet, sugared asphalt | Prevents overheating and traction-rolling, very long-lasting. |

Remember, this table is a starting point. Choosing the right compound is a dynamic process. It means you have to constantly "read" the track and be ready to make a change to stay ahead of your competition.

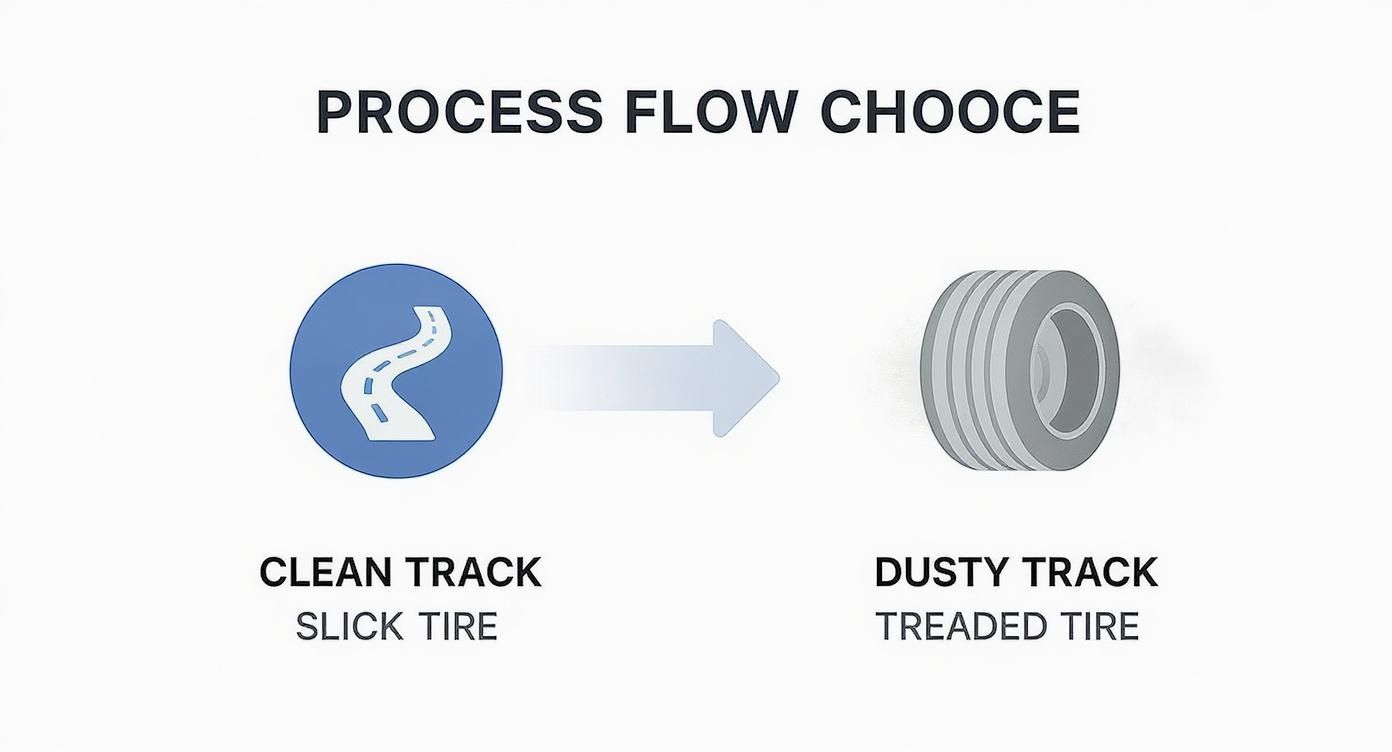

Choosing Your Contact Patch: Slicks vs. Treads

The real magic in RC racing happens right where the rubber meets the road—or carpet. This tiny area, known as the contact patch, is where every setup decision you make either pays off or sends you spinning. The most fundamental choice here is whether to run slick tires or ones with a tread pattern.

For on-road racers, this one decision dictates your car's ultimate potential for grip. Understanding why you'd choose one over the other is key to reading a track surface and making the call that leads to consistent, race-winning performance.

The Case for Maximum Grip: Slicks

Think about trying to stick a piece of tape to a smooth, clean surface. You’d press it down flat, getting as much of it to touch as possible for the best adhesion. Slick RC car tires work on the exact same principle. On a clean, dry, high-grip surface like prepped asphalt or racing carpet, slicks are the undisputed king.

By getting rid of any treads, grooves, or voids, a slick tire puts the maximum amount of rubber in direct contact with the track at all times. This creates the largest possible contact patch, which translates directly into the highest level of mechanical grip your car can generate. The entire surface of the tire works as one to create friction, letting you carry more speed through corners and accelerate harder on the exit.

On a properly prepared track, running a treaded tire is like willingly giving up lap time. Those grooves reduce the contact patch, meaning you're leaving free grip on the table that your competitors are absolutely using.

When Treads Become a Tactical Advantage

So if slicks offer the most grip, why do treaded tires even exist for on-road racing? The answer is simple: imperfect conditions. Treads become a crucial tuning tool the moment the track surface is anything less than ideal.

Picture a freshly swept track that still has that fine layer of dust on it, what racers often call a "green" track. A slick tire can struggle to find purchase here, almost hydroplaning on the dust. This is where a treaded tire can make a world of difference.

- Dusty or 'Green' Tracks: The small grooves or patterns in a treaded tire give it edges that can cut through the fine layer of dust or debris. This allows the main body of the tire to make better contact with the actual track surface underneath, bringing back a level of predictable grip.

- Damp or Wet Conditions: While dedicated rain tires are a whole other category, a light tread helps manage slightly damp patches. The channels give that bit of moisture a place to escape, preventing a layer of water from forming between the rubber and the track—which is what causes a total loss of traction.

- Low-Traction Surfaces: On some unprepared asphalt or polished concrete surfaces, a treaded pattern can generate more mechanical grip. It creates pressure points that bite into the surface more effectively than a smooth slick can. For a deeper dive into specific options, you can explore race-proven touring car tires like the Gravity RC G-SPEC Type C tires, which are designed for exactly these kinds of scenarios.

The growing popularity of RC racing is supported by a surprisingly robust local economy. For instance, the tire dealer sector in California now includes over 5,000 businesses, seeing steady growth of 2.8% annually between 2020 and 2025. While this is for full-size vehicles, the expanding supply chains and retail networks directly benefit hobbyists searching for specialized RC car tires. You can find out more about this industry's growth and its impact on niche markets and see how it helps us get the parts we need faster.

Mastering Tire Mounting and Balancing Like a Pro

Having the perfect set of RC car tires for the track conditions is only half the battle. If they aren't prepared and mounted flawlessly, all that potential grip goes right out the window. Top-level racers know that meticulous prep is a non-negotiable step that directly translates to faster, more consistent laps. This is where you gain a true competitive advantage before your car even hits the ground.

This isn't just about slapping rubber onto a wheel. It’s a methodical process to ensure a perfect bond, ideal balance, and total reliability under extreme racing loads. Getting this right eliminates those classic headaches, like a tire coming unglued mid-race or a mysterious vibration robbing you of speed on the main straight.

The Foundation: A Clean Start

Before any glue even comes out, you have to prep both the tire and the wheel. It's a critical first step. Think of it like painting a car—you'd never spray over a dirty, oily surface and expect it to stick. The same exact principle applies here. The enemy is the mould-release agent left over from manufacturing.

This oily residue is notorious for preventing CA (cyanoacrylate) glue from creating a strong, permanent bond. To get rid of it, you need to thoroughly clean the bead area of the tire and the mounting channel on the wheel. Most racers just use a simple cleaner like motor spray or isopropyl alcohol on a lint-free cloth. A clean, dry surface is what gives the glue something to really grab onto.

Gluing Tires the Right Way

Applying CA glue is a skill that takes a bit of finesse. The goal is a bond strong enough to handle thousands of RPMs, but not so rigid that it warps the tire's sidewall or bead. Too much glue can make the tire brittle, while too little risks a catastrophic failure during a race.

Follow these steps for a perfect glue job every time:

- Seat the Tire: First, carefully work the tire onto the wheel. Make sure the foam insert is sitting evenly inside and the tire bead is perfectly seated in the wheel’s channel on both sides.

- Peel and Apply: Gently pull back a small section of the tire bead away from the wheel. Apply a very thin line of medium-viscosity CA glue directly into the channel where the bead sits.

- Release and Bond: Let the bead fall back into place and press it firmly for a few seconds. This ensures a solid bond before you move to the next section. Work your way around the entire tire in small, manageable segments.

- Repeat on Both Sides: Once one side is done, flip the tire over and repeat the exact same process on the other side. Let the glue fully cure before doing anything else.

This process, powered by fast-acting cyanoacrylate adhesive, is what makes modern tire gluing possible. The quick-curing property is a lifesaver for trackside repairs, but it also demands a precise and careful technique to get it right.

The Importance of Balancing

Once your tires are glued, the final, critical step is balancing. At the incredible speeds on-road RC cars reach, even a tiny imbalance of a gram or two creates massive vibrations. This vibration doesn't just feel sloppy; it causes real problems by reducing traction, accelerating bearing and suspension wear, and scrubbing off valuable speed on the straights.

Balancing isn't an optional step for serious racers; it's mandatory. An unbalanced tire is like driving a full-size car with a wheel weight missing—the whole vehicle shakes, and performance suffers dramatically.

To balance your RC car tires, you'll need a dedicated tire balancer. These simple tools let the wheel spin freely, allowing the heaviest point to naturally settle at the bottom. To fix this, you add small amounts of balancing putty or tape to the opposite side of the wheel (the top) until the tire can stop in any random position without rotating on its own.

It might seem tedious, but perfectly balanced tires result in a smoother, faster, and more stable car. For those looking to optimize every aspect of tire prep, advanced tools like the Team Powers Vacuum Pump Master can help ensure inserts are perfectly seated for even better balance and consistency.

Advanced Setup Tuning With Additives and Break-In

The difference between a fast car and a winning car often boils down to that last one percent of setup. This is where you get into advanced techniques like tire break-in and the strategic use of additives—what everyone at the track just calls "sauce."

Mastering these skills turns your RC car tires from just another part into one of your most powerful tuning tools. It's what gives you the edge to dial in your car's handling for any track, on any day.

A brand-new tire, fresh out of the bag, is almost never ready to race. It's covered in a slick, shiny film left over from the manufacturing mould, and that needs to go before you can get any real grip. This is where breaking them in, or "scuffing," is absolutely essential.

The Critical First Laps: Breaking In New Tires

Think of it like a new pair of stiff leather shoes; they're not comfortable until you've worn them in a bit. RC car tires are the same. The whole point of breaking them in is to gently scrub off that slick outer layer. This opens up the pores of the rubber and creates a slightly textured surface that generates consistent grip from the very first lap.

A proper break-in means your tires are predictable from the moment the race starts. If you skip this, those first few laps will feel slippery and inconsistent as the tire surface changes with every corner.

You’ve got a couple of ways to do this:

- On-Track Scuffing: The simplest way is to just run a few easy laps. Don't push it. Just drive smoothly and let the track surface naturally wear the tire in.

- Tire Sanders: For more repeatable and even results, serious racers use a dedicated tire sander. This handy tool spins the tire against a fine-grit sandpaper, scuffing the entire surface perfectly every time.

Unlocking Grip With Tire Additives

Once your tires are prepped, the next level of tuning is all about tire additives, known universally in the pits as tire sauce. This is a chemical you apply to the tire surface that softens the rubber and massively increases grip. The sauce temporarily changes the compound, letting it bite into the track surface way more aggressively.

The application process is a pre-race ritual for competitive racers, and how you do it directly impacts performance. It usually involves using a dauber to apply the sauce, letting it soak into the rubber for a set amount of time, and then wiping off the excess before your run. That "soak time" is a key tuning variable—longer soaks generally mean more grip.

Experienced racers live by their stopwatches. A 15-minute soak might be perfect for a medium-grip track. On a high-bite surface, though, you might cut that back to 5 minutes to keep the car from traction-rolling. Timing is everything.

Using Sauce as a Powerful Setup Tool

Tire sauce is more than just a grip booster; it's one of the most effective tools for balancing your car's handling. By applying it strategically, you can fix common problems like understeer and oversteer with incredible precision.

Understeer, or a "push," is when the front end just doesn't want to turn into the corner. Oversteer is the opposite—the rear end feels loose and wants to spin out.

Here’s how you can use sauce to tune your way out of trouble:

- To Fix Understeer (More Front Grip): If your car isn’t turning in sharply enough, you need more bite at the front. You can get this by letting the sauce soak into the front tires for a longer time than the rears. Another trick is to sauce the full width of the front tires but only the inner half or two-thirds of the rears.

- To Fix Oversteer (More Rear Grip): If the back of the car feels sketchy, you need to give it more traction. Do this by letting the sauce soak into the rear tires longer than the fronts. Applying sauce to the full rear tire while only treating the inside half of the front will help calm the car down, especially on corner entry and exit.

This level of control turns your RC car tires into an active part of your setup. By tweaking application width and soak times, you can make small, precise changes that fix handling issues and shave precious tenths off your lap times. It's how you turn a good setup into a race-winning one.

How to Read Tire Wear and Plan Your Race Day Arsenal

Your RC car tires are constantly talking to you. After a hard run, the wear patterns on their surface tell a detailed story about your car's setup and how it's behaving on the track. Learning to read this story is like getting direct feedback from the car itself, letting you make precise adjustments instead of just guessing.

Understanding this feedback loop is what separates good racers from great ones. It turns tire wear from a simple sign of a spent part into a powerful diagnostic tool that helps you dial in your setup for more speed and consistency.

Diagnosing Handling from Tire Wear

Different wear patterns point directly to specific setup issues. Once you recognize these signs, you can quickly identify and fix problems with camber, toe, or even your driving style.

- Centre-Line Wear: If your tires are wearing out fastest right down the middle, it’s a classic sign of over-inflation or, more often in RC, an insert that's too hard. The tire is ballooning at high speeds, shrinking the contact patch and killing your grip.

- Feathering: When the tread develops a rough, feathered edge across its width, it usually points to a problem with your toe settings. This scuffing pattern means the tire is being dragged sideways as it rolls forward.

- Graining: This looks like tiny rolls of rubber forming on the tire's surface, almost always caused by overheating. It’s a clear signal that your compound is too soft for the track temperature, causing the rubber to tear away instead of wearing down smoothly.

A common mistake is to see wear and immediately replace the tire. The smart move is to first ask why it wore that way. Correcting the underlying setup issue—like adjusting camber to fix inner edge wear—will make your next set of tires last longer and perform better.

Building Your Race Day Tire Collection

Showing up to the track prepared for anything is crucial. You don't need to own every tire ever made, but a strategic collection will cover 90% of the conditions you'll face without breaking the bank.

Start by building a core set of slicks. For a typical asphalt season, focus on getting these compounds first:

- A medium-hard compound (e.g., 36-40 Shore): This will be your go-to tire for warm, high-grip conditions on race day.

- A medium-soft compound (e.g., 30-34 Shore): This is your ideal choice for cooler practice days or when the track surface isn't perfect.

- One set of treaded tires: Keep these on hand for dusty or damp "green" track conditions where slicks just can't find any bite.

This smart, minimal approach is also reflected in broader industry trends. In places like California, a focus on sustainability is encouraging the use of more durable materials—a mindset that benefits RC racers by promoting longer-lasting tire designs. To learn more, you can explore California's comprehensive tire recycling and management programs.

Questions From the Pits: Your RC Tire FAQ

Stepping into the world of on-road RC racing, you'll quickly find that tires are everything. They're the single most important part of your setup, and naturally, they're where a lot of questions come up. Here are some of the most common things we hear in the pits, with straightforward answers to get you up to speed.

How Should I Store My RC Tires?

Proper storage is the key to making your tires last and perform consistently. The best way to do it is to keep them in a cool, dark place, far away from direct sunlight and big temperature changes. UV light and heat are the biggest enemies of performance rubber, causing it to dry out, harden, and lose its grip.

Most seasoned racers keep their mounted tires in zip-top bags or sealed plastic tubs. This isn't just for organisation—it also traps the chemicals from tire additives, keeping them from evaporating and ensuring the rubber stays tacky. Pull a set out of a sealed bag, and they'll be race-ready, just like you left them.

What’s the Best Way to Clean RC Car Tires?

Clean tires are fast tires. After every run, your tires are covered in dust, track debris, and old additive. To get consistent performance, you have to get that stuff off. A quick wipe-down with a lint-free rag and a good tire cleaner or a simple, mild degreaser is all it takes.

You want to avoid harsh chemicals that can strip the oils out of the rubber and make it brittle. The goal is just to clean the surface so your next coat of tire sauce can bite into fresh rubber. For a deeper clean between race days, a little Simple Green and water with a soft brush works wonders.

Can I Reuse Wheels After I’ve Pulled the Old Tires Off?

Absolutely, but you've got to put in the prep work. The real challenge is getting every last bit of old CA glue off the wheel's mounting bead. If you leave any hardened glue behind, the new tire won't sit flat, leading to a wobbly, unbalanced wheel and a bond that's just waiting to fail.

A classic trackside trick is to use acetone to dissolve the old CA glue. Soaking the wheel helps break it down, but be careful—acetone can make some plastics brittle. Once it's softened, you can use a hobby knife to carefully scrape the residue away for a perfectly clean surface.

How Often Should I Be Replacing My Tires?

There's no magic number here. A tire's lifespan depends completely on the compound, the track surface, and your car's setup. A set of super-soft tires might only be good for a single race day on a high-grip, abrasive asphalt track. On the other hand, a harder compound could last for weeks of club racing on carpet.

The real signal is a drop-off in performance. When your lap times start to fade, or the car suddenly feels inconsistent and hard to drive, it's a good sign your tires are done. Before every run, give them a quick visual check for excessive thinning of the carcass or any significant graining.

At digital-rc, we stock the high-performance tires and accessories that racers rely on to stay competitive. Find the right set for your car and get back to winning at https://digitalrc.ca.